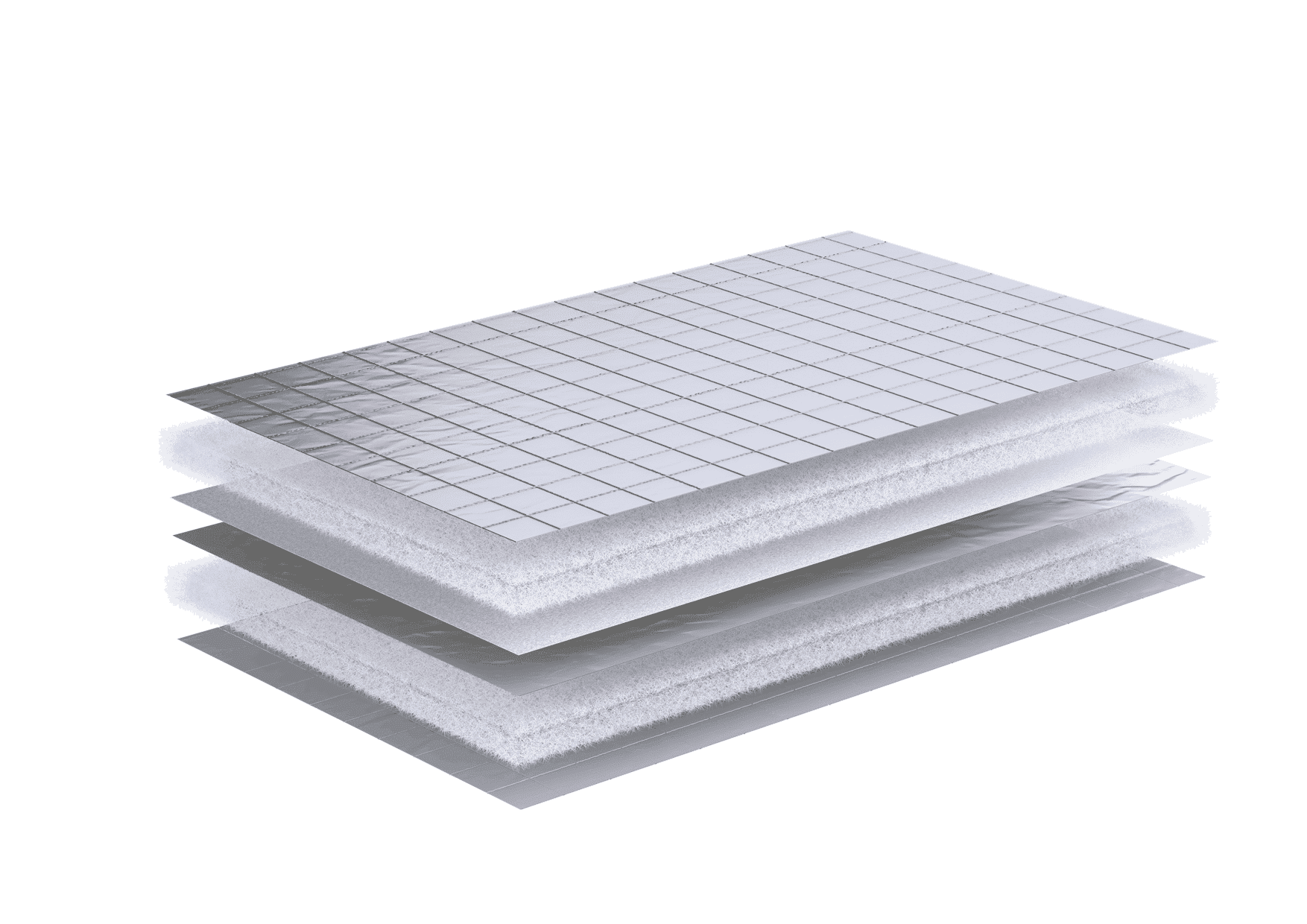

Silverskin thermal covers help protect your temperature-sensitive products against thermal damage in transit. Our thermal covers slow down temperature exchange by guarding against short temperature spikes that can threaten your temperature sensitive products’ integrity, often experienced during loading and off-loading, cross docking and even the most demanding packing and warehouse conditions.

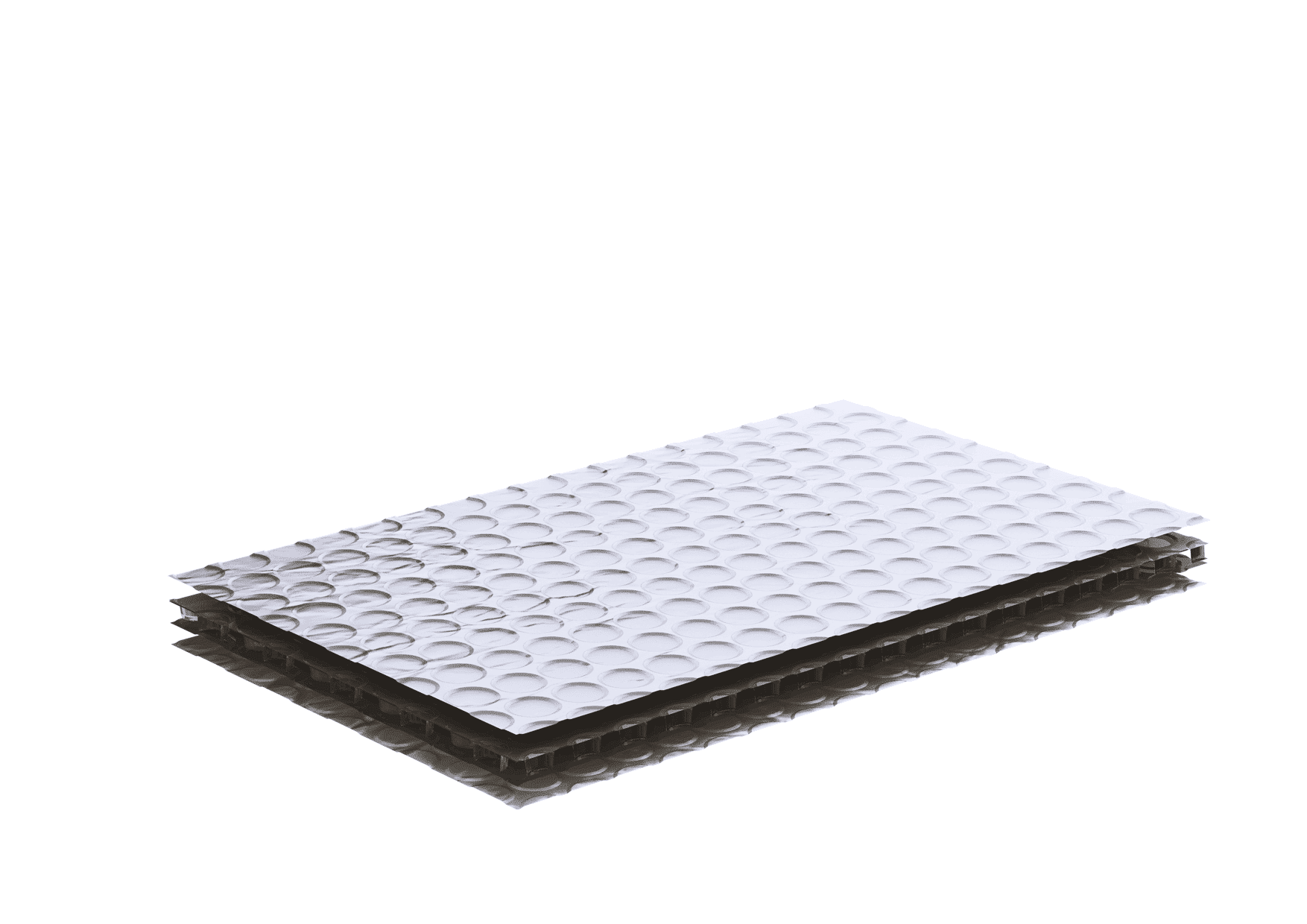

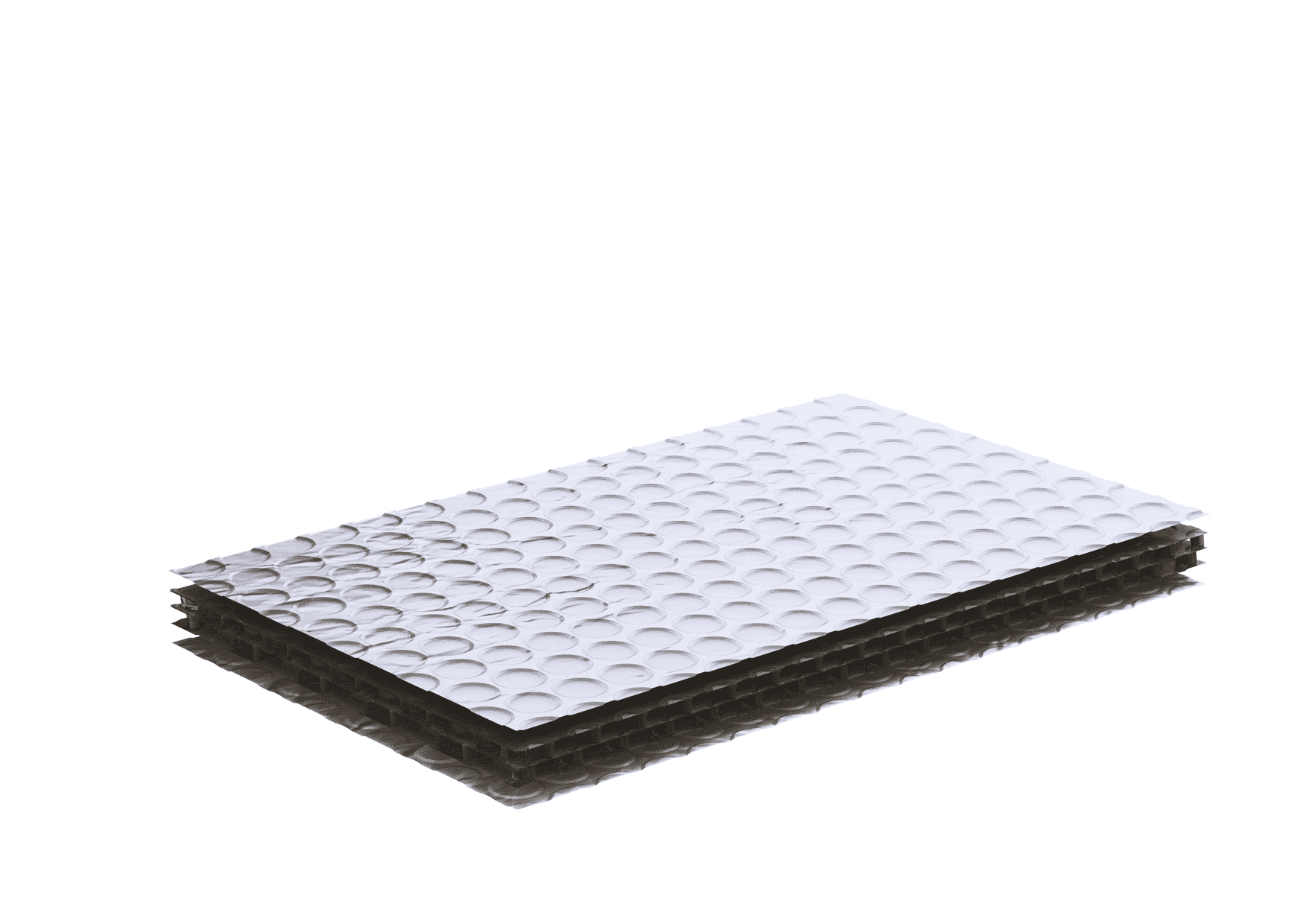

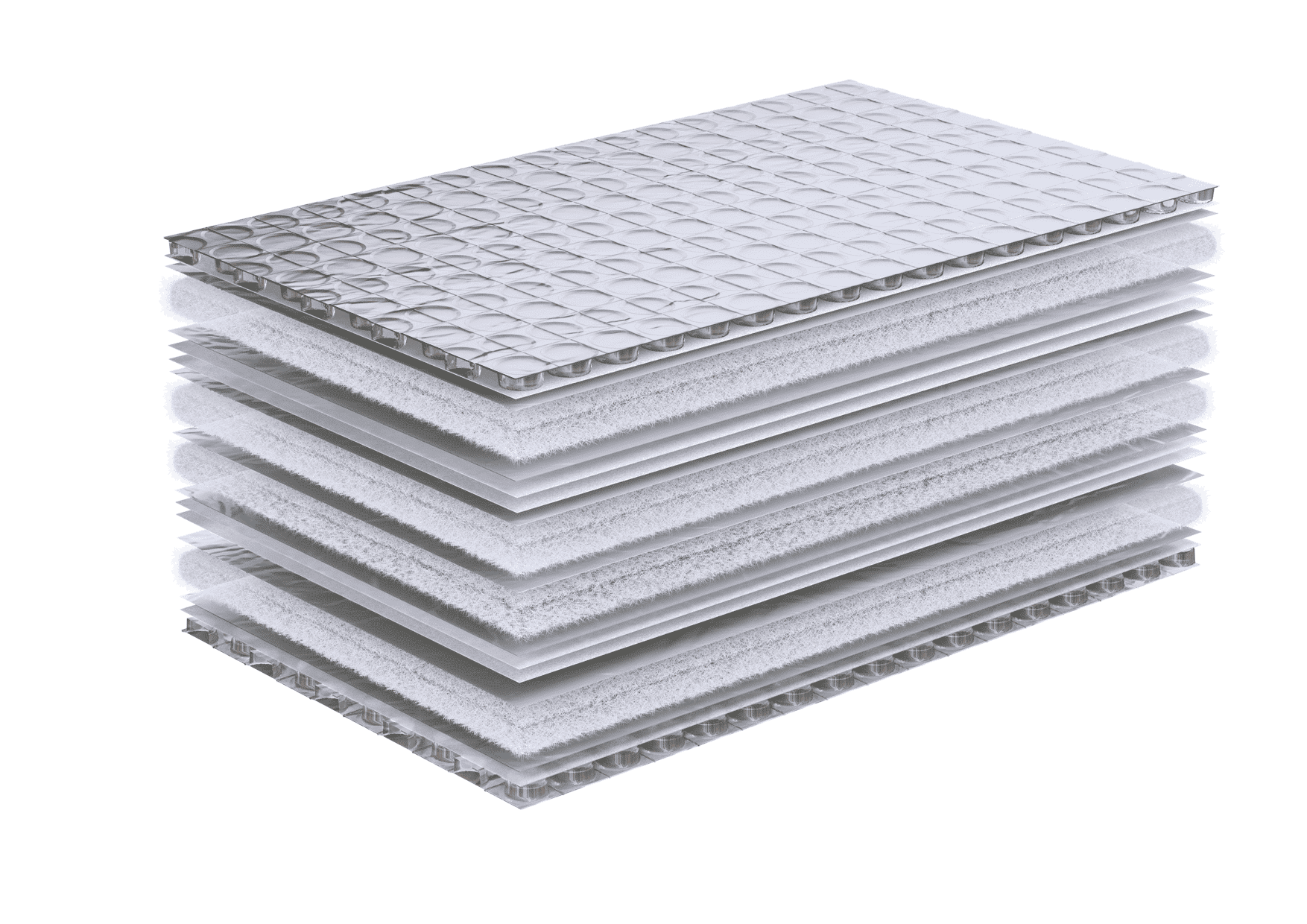

Manufactured from strong, flexible, protective insulation materials and available in grades to suit different performances and budgets, our portfolio comprises thermal covers that offer thermal protection across all modes of transport. This helps keep temperature sensitive products safe within their specified ship to label-claims throughout the duration of their journey.

Silverskin Performance Features

- Various grades and thicknesses

- Reflects solar radiation

- Water resistant

- Reduces temperature exchange

- Tamper evident security barrier

- Minimal storage requirements

- Security/theft protection

- Protects during cross docking operations